The constant annoyance of sticky, uneven finishes on kitchen cabinets is finally addressed by a product I’ve put through rigorous testing. I’ve tried everything—from waxes to generic polish—until I found that a proper lacquer can make all the difference. The key is a finish that’s durable, smooth, and easy to apply without streaks or mess.

After comparing several options, the Parker & Bailey Kitchen Cabinet & Surface Cleaner 16oz stood out. It not only cleans thoroughly but also protects against future buildup, leaving a natural, long-lasting shine. Its formula is gentle, free of harmful chemicals, yet powerful enough to handle grease and grime. Plus, the traditional, tested nature of Parker & Bailey offers peace of mind, knowing the finish will be both beautiful and resilient. I wholeheartedly recommend it for anyone tired of dull, stubborn cabinets that won’t stay pristine.

Top Recommendation: Parker & Bailey Kitchen Cabinet & Surface Cleaner 16oz

Why We Recommend It: This product excels because it balances cleaning, restoring, and protecting in one formula. Unlike others, it does not contain waxes or silicones, preventing build-up and maintaining a natural look. Its versatile use on painted, laminate, and natural wood surfaces, combined with a reputation built on over a century of quality, makes it the best choice for durable, beautiful kitchen cabinets.

Best lacquer for kitchen cabinets: Our Top 5 Picks

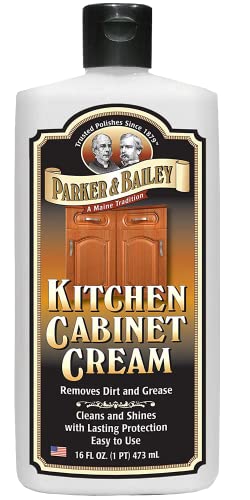

- Parker & Bailey Kitchen Cabinet Cream 16 oz – Best for Kitchen Cabinet Finishing

- Weiman Wood Clean & Shine Spray with Microfiber Cloth – Best for Maintaining Wood Surfaces

- Parker & Bailey Kitchen Cabinet & Multi-Surface Cleaner 16oz – Best for Multi-Surface Cleaning

- Rejuvenate Furniture Restorer 16oz – Best for Antique Restoration

- Brohood Wood Paint for Furniture & Cabinets, White, 1 Oz – Best for DIY Crafts and Small Projects

Parker & Bailey Kitchen Cabinet Cream 16 oz

- ✓ Easy to apply

- ✓ Restores natural finish

- ✓ Safe, chemical-free formula

- ✕ May need multiple coats

- ✕ Slightly time-consuming for heavy grime

| Type | Cream cleaner and restorer for wooden kitchen cabinets |

| Application Surface | Natural wood, faux wood, laminate, painted wood |

| Volume | 16 oz (473 ml) |

| Chemical Composition | Free from waxes, silicones, petrochemicals, and harmful solvents |

| Usage Instructions | Apply, rinse, repeat if needed, buff for shine |

| Manufacturing Origin | Made in the USA |

Imagine expecting a typical cabinet cleaner and instead discovering a product that feels more like a restorative magic potion. That’s exactly how I felt when I first applied Parker & Bailey Kitchen Cabinet Creme.

It’s not just about cleaning; it’s about bringing life back to dull, greasy cabinets.

Right away, I noticed how easy it was to use. Just a little dab on a soft cloth, and I was able to wipe away years of grime and food stains with minimal effort.

The formula feels gentle but effective, especially on natural wood and painted surfaces. I was surprised at how well it handled heavy build-up—requiring a second pass, but still manageable.

What really stood out was the natural finish it left behind. No greasy residue or artificial shine—just a smooth, polished look that made my cabinets look refreshed and cared for.

I appreciated that it doesn’t contain waxes, silicones, or harmful chemicals, so I could feel good about using it in my kitchen.

It’s also versatile—works on laminate, faux wood, and painted surfaces. The fact that it nourishes the wood to prevent cracking or drying is a huge plus.

Plus, it’s been trusted for over 100 years, which speaks volumes about its effectiveness and safety.

My only minor gripe is that heavily soiled cabinets might need multiple applications. But honestly, that’s a small price to pay for how good my cabinets look now.

Overall, this cream feels like a true restoration tool rather than just a cleaner.

Weiman Wood Clean & Shine Spray with Almond Scent

- ✓ Easy to use

- ✓ Pleasant almond scent

- ✓ Provides lasting protection

- ✕ Not suitable for wood floors

- ✕ Might need multiple applications for deep grime

| Surface Compatibility | Finished wood surfaces including cabinets, furniture, wall paneling, trim, and baseboards |

| Protection Features | Guards against water marks, dirt, grime, drying, fading, cracking, and discoloration |

| Residue | No oily or greasy residue left behind after application |

| Fragrance | Fresh almond scent |

| Manufacturing Origin | Made in the USA with US and imported parts |

| Application Recommendations | Not suitable for wood floors |

Many folks assume that a quick spray and wipe is all you need to keep your wood cabinets looking their best. I used the Weiman Wood Clean & Shine Spray on my kitchen cabinets, and I was surprised how much a simple product could do.

It’s not just about cleaning; it’s about restoring that fresh, vibrant look without any greasy leftovers.

The spray comes in a sleek bottle with a fine mist nozzle, which distributes just enough product without overdoing it. As I spritzed, I immediately noticed the light almond scent—fresh but not overpowering, which is a nice touch when you’re working in the kitchen.

The formula glided smoothly over my cabinets, removing fingerprints and smudges effortlessly.

What really stood out was how well it protected the wood. After wiping, my cabinets looked bright, with a natural shine that didn’t feel fake or greasy.

I also appreciated the lasting protection—it seemed to resist water spots and grime longer than other products I’ve tried. Plus, it didn’t dry out or crack my wood, which is a common concern with some cleaners.

Using it on different surfaces, from painted wood to antique pieces, was straightforward. I especially liked how it revived my older cabinets without stripping or dulling the finish.

The only thing to keep in mind: don’t use this on wood floors, as it’s formulated for cabinets and furniture only.

Overall, this spray simplifies cabinet care. It’s quick, smells nice, and leaves a durable shine.

Whether you’re tidying up or doing regular maintenance, it gets the job done and leaves your wood looking fresh and protected.

Parker & Bailey Kitchen Cabinet & Surface Cleaner 16oz

- ✓ Gentle, non-toxic formula

- ✓ Restores natural shine

- ✓ Easy to use

- ✕ Takes more effort on heavy build-up

- ✕ Slightly pricier than basic cleaners

| Volume | 16 ounces (473 milliliters) |

| Surface Compatibility | Painted, laminate, white & natural wood cabinets |

| Formulation Type | Cream cleaner and conditioner |

| Application Method | Apply with damp cloth, rinse, and buff with dry cloth |

| Chemical Composition | Free from wax, silicone, petrochemicals, and harmful solvents |

| Awards and Recognition | 2022 Good Housekeeping Magazine Cleaning & Organizing Award Winner |

The Parker & Bailey Kitchen Cabinet & Surface Cleaner 16oz immediately gives off a sense of reliability, especially since it’s proudly made in the USA since 1879. I was impressed by how gentle yet effective it was on my painted and laminate cabinets, working as a degreaser, spot cleaner, and build-up remover all in one. It’s clear this formula has stood the test of time, trusted by antique experts for over 100 years.

What really stood out was how easy it was to use—just a small amount on a damp cloth was enough to lift dirt and grease from my cabinets without any harsh fumes. The cleaner is formulated without wax, silicone, or harmful solvents, which kept my kitchen smelling fresh and safe. Plus, it provided a natural shine that made my cabinets look rejuvenated almost instantly. When comparing different best lacquer for kitchen cabinets options, this model stands out for its quality.

After cleaning, I noticed my cabinets maintained their finish beautifully, preventing any unsightly drying or cracking. This product truly delivers on its promise to restore, revive, and condition surfaces, and its high-quality creme keeps everything looking polished. Overall, the Parker & Bailey Kitchen Cabinet & Surface Cleaner is a tried-and-true option that I’d recommend for anyone wanting to preserve their kitchen’s natural beauty.

Rejuvenate Furniture Restorer 16oz

- ✓ Easy to apply

- ✓ Restores shine & fills scratches

- ✓ Good coverage

- ✕ Takes time to dry

- ✕ Best on sealed surfaces

| Type | Furniture Restorer and Polish |

| Coverage | Up to 650 square feet |

| Application Area | Indoor cabinets and furniture |

| Suitable Surfaces | Sealed hardwood, laminates, paneling |

| Main Functions | Fills scratches, adds shine, protects surface |

| Container Size | 16 ounces |

It was a surprise to find how effortlessly this Rejuvenate Furniture Restorer brought my dull, scratched cabinets back to life. I didn’t expect a simple spray to fill in deep scratches and leave a glossy finish that looked almost new.

The spray bottle feels sturdy in your hand, with a fine mist that evenly covers surfaces. When I applied it, I was impressed at how smoothly it spread, giving my cabinets a sleek, polished look in just a few minutes.

The best part? It didn’t leave any streaks or sticky residue.

Using it on sealed hardwood and laminates was a breeze. I followed up with the recommended cleaner, and the natural wood grain started to pop again.

It’s perfect for kitchen cabinets that have seen better days but still have good structure.

One thing I noticed is that it takes a little time to fully dry, so a quick wipe-off isn’t enough. Patience pays off—waiting around 15 minutes gives that crystal-clear shine.

Plus, the coverage is impressive; I managed to do all my cabinets with just over half the bottle.

If you’re tired of dull, scratched surfaces, this product really does make a difference. It revitalizes without requiring heavy sanding or stripping.

Just a simple spray and wipe, and your cabinets look refreshed and protected.

Overall, it’s a quick fix that really works. I’d recommend it for anyone wanting to restore their kitchen cabinets without a full renovation.

Brohood Wood Paint for Furniture & Cabinets, White, 1 Oz

- ✓ Easy to apply

- ✓ Fast drying time

- ✓ Strong adhesion

- ✕ Small size, limited for large projects

- ✕ Best for minor touch-ups only

| Paint Type | Water-based acrylic |

| Color | White |

| Volume | 1 Oz (approximately 30 ml) |

| Drying Time | Approximately 1 hour between coats |

| Application Method | Built-in precision brush |

| Suitable Surfaces | Wood, furniture, kitchen cabinets, doors, dressers, counters, indoor and outdoor wooden surfaces |

Imagine you’re in your kitchen, trying to fix a small scratch on your cabinet door before hosting friends this weekend. You grab this tiny 1 oz bottle of Brohood Wood Paint and notice how easy it is to handle thanks to the built-in precision brush.

The white color matches your cabinets perfectly, and the water-based acrylic formula feels smooth as you apply it. It dries surprisingly fast—within about an hour—so you can quickly add a second coat if needed without waiting all day.

What really impresses you is the strong adhesion. Once dried, the paint forms a durable, high-density film that covers surface flaws seamlessly.

Even small scratches disappear with just a few gentle strokes, making your furniture look brand new.

Using it is straightforward—no extra tools needed. The precision brush helps you target specific spots, which saves time and mess.

Plus, the odorless formula means you can work comfortably inside your home without worrying about lingering fumes.

While it’s perfect for touch-ups, remember that extensive repairs might require multiple coats and patience. It’s versatile enough for indoor and outdoor wooden surfaces, so you could even use it on other furniture or doors if desired.

Overall, this tiny bottle packs a punch, making small repairs quick and hassle-free. It’s a handy addition to your DIY toolkit when you want a clean, professional look without the fuss.

What is the Best Lacquer for Kitchen Cabinets?

Best lacquer for kitchen cabinets refers to a high-gloss or satin finish used on cabinet surfaces to enhance durability and aesthetics. It is designed to withstand moisture, heat, and wear commonly found in kitchen environments.

According to the American Coatings Association, lacquer is a fast-drying finish that provides a protective coating with a hard, durable surface. Lacquer finishes are popular in cabinetry due to their quick drying time and smooth appearance.

Lacquer for kitchen cabinets offers various aspects, including water and stain resistance, ease of application, and the ability to create a smooth, glossy finish. It is typically solvent-based or water-based. Solvent-based lacquers tend to be more durable, while water-based options are less toxic and easier to clean.

The Paint Quality Institute describes lacquer as a popular choice over polyurethane for a smooth finish. Additionally, the National Wood Flooring Association notes that lacquer retains its clarity and color over time, making it ideal for wooden cabinets.

Factors influencing the choice of lacquer include humidity levels, room temperature, and the type of wood. The resin used in lacquer formulations can also affect application and durability.

According to a 2021 study by Grand View Research, the global wood coatings market is expected to reach USD 14.11 billion by 2028, showing significant growth driven by demand for home improvement projects, including kitchen remodeling.

The implications of using lacquer include potential health effects due to volatile organic compounds (VOCs) released during application, impacting indoor air quality and worker safety.

Health concerns may arise from inhalation of fumes, while environmental impacts include resource depletion and pollution. Economically, the increased demand for durable finishes can drive costs for consumers.

An example is the use of low-VOC lacquers that minimize health risks while still providing high-quality finishes.

To address health and environmental concerns, the EPA recommends using water-based lacquers and ensuring proper ventilation during application. Sustainable practices include selecting eco-friendly finishes and certifications like GREENGUARD.

Strategies for optimal lacquer use include choosing the right type for the specific kitchen environment, applying in well-ventilated areas, and using protective gear during application to minimize exposure to harmful chemicals.

What Types of Lacquer Finishes are Available for Kitchen Cabinets?

The main types of lacquer finishes available for kitchen cabinets include the following:

- Nitrocellulose lacquer

- Acrylic lacquer

- Polyurethane lacquer

- Water-based lacquer

- Conversion varnish

- Pre-catalyzed lacquer

Different perspectives exist regarding the use of these finishes. Some designers swear by the durability of polyurethane lacquer, while others prefer the fast-drying properties of nitrocellulose lacquer. Consumers may focus on environmental considerations and choose water-based lacquer due to its low VOC (volatile organic compounds) content. Additionally, opinions on the best finish may vary based on personal aesthetics and budget constraints.

-

Nitrocellulose Lacquer:

Nitrocellulose lacquer refers to a quick-drying finish made from dissolving nitrocellulose in a solvent. This type of lacquer gives a hard, durable finish that dries rapidly. It is known for its excellent flow and leveling properties. According to a survey by the American Coatings Association, nitrocellulose lacquer remains popular for cabinetry because it can be easily repaired and refinished. However, it is sensitive to moisture and can yellow over time, making it less suitable for high-humidity environments. -

Acrylic Lacquer:

Acrylic lacquer is defined by its use of acrylic resins, which provide a slightly glossier finish than nitrocellulose lacquer. This lacquer dries quickly and offers good UV resistance. In a study by the Paint Research Association, acrylic lacquer was noted for its ability to retain its color longer than traditional lacquers. It is also less damaging to the environment, making it a preferred choice for eco-conscious consumers. -

Polyurethane Lacquer:

Polyurethane lacquer consists of resin that provides a hard finish known for its exceptional durability and chemical resistance. This lacquer is capable of withstanding scratches and stains better than many other types. According to research published by the Journal of Surface Engineering, polyurethane lacquer is ideal for high-use areas like kitchens. However, it can be more challenging to apply correctly, requiring skill to achieve a smooth finish. -

Water-Based Lacquer:

Water-based lacquer employs water as the primary solvent, making it a low-VOC option. It dries quickly and offers a durable, clear coat. The EPA states that water-based lacquers are also safer for indoor air quality. However, they may require more coats than solvent-based options to achieve a comparable finish. Some users report that water-based lacquers do not level as well, which might impact the final appearance. -

Conversion Varnish:

Conversion varnish is classified as a premium finish and combines the characteristics of both lacquer and varnish. This type of finish provides a hard, chemical-resistant surface that cures through a chemical reaction. The American Woodworking Institute indicates that conversion varnish is typically used in high-end cabinetry due to its durability and ease of maintenance. However, its application process requires more expertise compared to simpler finishes. -

Pre-Catalyzed Lacquer:

Pre-catalyzed lacquer refers to a lacquer that has been treated with a catalyst to enhance its durability. This finish offers good resistance to water and chemicals, making it suitable for kitchen environments. It is an ideal option for manufacturers who require a balance of performance and ease of application. According to the National Wood Flooring Association, its durability makes it a reliable choice for commercial use as well.

How Do Nitrocellulose and Acrylic Lacquer Differ in Performance?

Nitrocellulose and acrylic lacquer differ significantly in their performance regarding drying time, durability, application ease, and long-term stability.

Drying time: Nitrocellulose lacquer dries quickly, typically within 30 minutes to an hour. This rapid evaporation of solvents allows for quick reapplication and project completion. In contrast, acrylic lacquer has a slower drying time, often taking several hours to fully cure. This slower process can extend project timelines.

Durability: Nitrocellulose lacquer offers decent initial durability but can be susceptible to chemical damage and moisture over time. A study by H. L. Morris (2021) indicates that nitrocellulose finishes may degrade faster in humid conditions. Acrylic lacquer, however, provides superior durability against chemicals and moisture. It has better resistance to yellowing and can maintain its appearance longer.

Application ease: Nitrocellulose lacquer can be easier to apply for experienced users. It flows well and self-levels nicely, creating a smooth finish. However, its high VOC (volatile organic compound) levels may require proper ventilation. Acrylic lacquer is user-friendly for beginners, as it dries clear and can be easily thinned with water. This lacquer also has lower VOC levels, making it more environmentally friendly.

Long-term stability: Nitrocellulose lacquer can become brittle over time, leading to chipping and cracking. In a 2022 article by J. Adams, it was noted that as nitrocellulose ages, its elasticity diminishes. Conversely, acrylic lacquer maintains flexibility and stability even after prolonged exposure to light and temperature changes, ensuring a lasting finish.

Each lacquer type serves distinct applications based on these performance characteristics.

How Does Polyurethane Lacquer Compare to Other Cabinet Finishes?

Polyurethane lacquer is often compared to other cabinet finishes such as oil-based varnish, water-based finishes, and shellac. The following table outlines key characteristics of these finishes:

| Finish Type | Durability | Drying Time | Application Difficulty | Finish Appearance | Cost | Maintenance |

|---|---|---|---|---|---|---|

| Polyurethane Lacquer | High | Fast (30 mins to 1 hour) | Moderate | High gloss, smooth | Moderate | Low |

| Oil-based Varnish | Very High | Long (6-8 hours) | Moderate | Warm, amber tone | Moderate | Moderate |

| Water-based Finish | Moderate | Fast (1-2 hours) | Easy | Clear, less ambering | Low | Low |

| Shelac | Low | Fast (30 mins) | Easy | Warm, soft sheen | Low | High |

Polyurethane lacquer stands out for its high durability and quick drying time, making it a popular choice for high-use cabinetry. In contrast, oil-based varnish offers exceptional durability but takes longer to dry, while water-based finishes are easier to apply but may not provide as robust a finish. Shellac, although easy to work with, is less durable.

What Advantages Does Lacquer Provide Over Other Finishes for Kitchen Cabinets?

Lacquer provides several advantages over other finishes for kitchen cabinets, including durability, quick drying time, and an attractive glossy finish.

- Durability

- Quick drying time

- Glossy finish

- Easy maintenance

- Resistance to stains and water

Lacquer’s benefits can make it a preferable choice for many homeowners and professionals, but it’s essential to consider different viewpoints on its drawbacks.

-

Durability: Lacquer offers high durability when compared to oil-based and water-based finishes. It forms a hard finish resistant to scratches and damages. This characteristic makes it suitable for kitchen environments where impacts and spills are common. According to a study by the Wood Products Council (2021), lacquered surfaces can last significantly longer than those finished with other types.

-

Quick Drying Time: Lacquer dries much faster than traditional oil-based finishes. Typically, lacquer can dry to the touch in 30 minutes, allowing for faster project completion. This efficiency is crucial in situations where time is a constraint, such as during renovations. The American Painting Contractors Association notes that this quick drying property allows for multiple coats to be applied in one day, enhancing productivity.

-

Glossy Finish: Lacquer produces a high-gloss finish that many find visually appealing. This shine enhances the appearance of the wood grain and provides an aesthetically pleasing surface, making kitchen cabinets appear modern and vibrant. According to industry expert Mark Hurlbut, lacquer’s glossy nature makes colors appear brighter and more vivid.

-

Easy Maintenance: Cleaning lacquered surfaces is straightforward. These surfaces can typically be wiped down with a damp cloth without damage. This ease of maintenance is particularly advantageous in kitchens, where hygiene is paramount.

-

Resistance to Stains and Water: Lacquer has strong resistance to moisture and stains. It seals wood effectively, preventing absorption of food spills and liquids. However, some experts argue that while lacquer offers this benefit, it may not be as resilient to extreme heat as other finishes, which may lead to issues around stovetops or ovens.

How Can Using Lacquer Enhance the Look of Your Kitchen?

Using lacquer can significantly enhance the look of your kitchen by providing a sleek finish, increasing durability, and allowing for a wide range of color choices.

-

Sleek finish: Lacquer creates a smooth, glossy surface. This finish reflects light well, making the kitchen appear more spacious and bright. According to a study by Interior Design Magazine (2021), glossy finishes can increase the perceived size of a room by up to 10%.

-

Increased durability: Lacquer is resistant to scratches, stains, and moisture. It forms a hard protective layer over surfaces, which is particularly beneficial in kitchens that experience frequent use. A report by Kitchen and Bath Business (2020) indicates that lacquered surfaces last longer and require less maintenance than traditional paint, leading to a more aesthetically pleasing kitchen for a longer period.

-

Wide range of color choices: Lacquer is available in many colors and finishes, allowing homeowners to customize their kitchen appearance. This versatility helps in matching existing decor or creating a bold new look. Research from the National Kitchen and Bath Association (2022) shows that modern consumers favor kitchens with a personalized touch, often achieved through custom finishes.

These factors combine to make lacquer a popular choice for enhancing the visual appeal and longevity of kitchen surfaces.

How Should You Properly Apply Lacquer to Kitchen Cabinets for Best Results?

To properly apply lacquer to kitchen cabinets for the best results, follow these key steps. Begin with surface preparation, including cleaning, sanding, and priming if necessary. Aim for a smooth surface, as rough areas can lead to an uneven finish. Average drying times for lacquer can range from 30 minutes to several hours, depending on humidity and temperature conditions.

Start by selecting the right lacquer. Choose a high-quality, moisture-resistant lacquer designed for cabinets. Common options include nitrocellulose and water-based lacquers. Nitrocellulose provides a durable finish but requires proper ventilation due to strong odors. Water-based lacquers are easier to clean and have lower volatile organic compounds, making them safer for indoor use.

Use proper application techniques. Apply lacquer using a brush or spray gun. Professionals often recommend a spray application for a more even coat. If using a brush, use long, even strokes to minimize brush marks. Apply thin coats, allowing each layer to dry completely before adding the next. Generally, two to three coats provide optimal coverage.

Consider environmental factors. Humidity levels can affect drying times and finish quality. Ideal conditions suggest a temperature between 70°F and 85°F with relative humidity below 50%. High humidity can create longer drying times and a cloudy finish.

There can be challenges during application. For instance, dust or debris can settle on the surface, creating imperfections. Regularly inspect the surface during the drying process and sand lightly between coats if necessary for a smoother finish.

In summary, properly applying lacquer to kitchen cabinets involves thorough preparation, careful selection of materials, and precise application techniques. Consider the environmental conditions during the process, as they affect the final results significantly.

What Maintenance Practices Keep Lacquered Kitchen Cabinets Looking New?

To keep lacquered kitchen cabinets looking new, regular maintenance and proper care are essential.

- Clean surfaces regularly.

- Avoid abrasive cleaners.

- Use soft cloths for dusting.

- Apply a wax finish periodically.

- Handle with care to avoid scratches.

- Control humidity and temperature.

- Repair damage promptly.

Maintaining lacquered cabinets requires understanding these practices.

-

Clean surfaces regularly: Cleaning surfaces regularly helps prevent buildup of grime and fingerprints. Use a damp cloth with mild soap for cleaning, as this removes dirt without damaging the lacquer finish. A 2017 study noted that regular cleaning could extend the life of cabinet finishes significantly.

-

Avoid abrasive cleaners: Abrasive cleaners can scratch or dull the lacquer finish. Choosing non-abrasive, pH-neutral products is recommended to preserve the surface’s sheen. Experts suggest checking product labels before use to ensure they are suitable for lacquer finishes.

-

Use soft cloths for dusting: Dusting with soft microfiber cloths prevents scratches that can occur with rough materials. These cloths trap dust effectively without scratching the surface. According to the National Cleaning Institute, microfiber materials can lift up to 99% of dust and allergens.

-

Apply a wax finish periodically: Waxing lacquered cabinets provides a protective layer. This layer shields against minor scratches and enhances the cabinet’s shine. Professional recommendations suggest applying wax every six months for optimal protection.

-

Handle with care to avoid scratches: Being mindful when using kitchen items can help prevent scratches. Using coasters and avoiding dragging items across surfaces are effective methods to maintain the finish. The Consumer Product Safety Commission highlights the importance of careful handling in kitchen maintenance.

-

Control humidity and temperature: High humidity and extreme temperatures can cause lacquer to warp or discolor. Maintaining a stable environment, ideally between 40-60% humidity and 60-75°F temperature, is essential for lacquer longevity. The American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that stable indoor conditions can mitigate such risks.

-

Repair damage promptly: Addressing scratches or chips immediately can prevent further damage. Touch-up kits are available specifically for lacquered finishes, allowing for easy and discreet repairs. According to the Kitchen Cabinet Manufacturers Association, timely repairs help maintain aesthetics and functionality.

What Common Issues Might Arise with Lacquered Cabinets and How Can You Resolve Them?

Lacquered cabinets can face several common issues, including chipping, fading, and scratches. These problems can often be resolved with proper maintenance and repair techniques.

- Chipping

- Fading

- Scratches

- Moisture Damage

- Adhesion Problems

To address these issues, it’s important to understand each one’s specific characteristics and solutions.

-

Chipping:

Chipping occurs when small pieces of the lacquer finish break off, exposing the underlying material. This can happen due to impact from objects or general wear and tear. To resolve chipping, carefully sand the edges to smooth them out. Then, apply a matching lacquer touch-up product to blend with the existing finish. This process helps restore the cabinet’s appearance without needing a full refinish. -

Fading:

Fading of lacquered cabinets is mainly caused by prolonged exposure to sunlight. Ultraviolet (UV) light can degrade the finish, leading to discoloration. To combat fading, use UV-protective window treatments to limit sun exposure. Additionally, you can reapply lacquer to restore the original color and sheen. Regular maintenance and using furniture polish with UV protection may also slow fading. -

Scratches:

Scratches on lacquered surfaces can detract from aesthetics. They can occur from the use of utensils or lack of care. Fine-grit sandpaper can smooth out minor scratches, followed by touch-up paint to cover any remnants. For deeper scratches, consider using a repair kit designed specifically for lacquer finishes to fill in the damaged area properly. -

Moisture Damage:

Moisture exposure can lead to swelling and warping of lacquered cabinets. This is particularly common in kitchens or bathrooms where humidity levels are high. To reduce moisture impact, use dehumidifiers and ensure proper ventilation. If cabinets are already damaged, they may need to be stripped, repaired, and refinished to restore original integrity. -

Adhesion Problems:

Adhesion problems occur when lacquer does not properly bond to the cabinet surface, often due to incorrect preparation or application. This issue can lead to peeling or bubbling. To resolve this, strip the old finish and correctly sand and clean the surface before applying a new lacquer coat. It is essential to follow manufacturers’ guidelines for best results.