As the holiday season approaches, it’s the perfect time to refresh your kitchen and protect those freshly painted cabinets. After hands-on testing, I can tell you how important it is to find a product that guards against water marks, grease, and fading—without leaving a greasy residue. My go-to is the Weiman Cabinet & Wood Clean & Shine Spray, Almond Scent. It’s light, effective, and leaves a subtle, fresh scent that’s never overwhelming.

This spray not only restores shine but offers lasting protection against everyday messes and drying, which is exactly what you want for your beloved painted surfaces. Unlike some polishes that build up and dull over time, it protects without waxes or silicones, keeping your cabinets looking bright and new longer. After comparing it to cream-based restorers and ceramic coatings, I find its versatility and quick spray-on application make a real difference. You’ll love how effortless it is to maintain your cabinets while keeping them protected and beautiful. Trust me, this is the friend-approved choice for long-lasting, effective cabinet care!

Top Recommendation: Weiman Cabinet & Wood Clean & Shine Spray, Almond Scent

Why We Recommend It: This product stood out because it provides a light, protective coating that guards against water marks, dirt, and fading without buildup. Its spray-on format makes application quick and even, unlike creams that require buffing, and it leaves behind a fresh scent. It’s formulated to prevent cracking and discoloration, making it ideal for painted cabinets. Compared to others, like the cream from Parker & Bailey which needs more effort with multiple coats, or the ceramic coating spray that’s better suited for non-porous surfaces, the Weiman spray strikes the perfect balance of ease, protection, and longevity for painted wood surfaces.

Best product to protect painted kitchen cabinets: Our Top 5 Picks

- Weiman Wood Clean & Shine Spray with Almond Scent – Best for Regular Cleaning and Shine

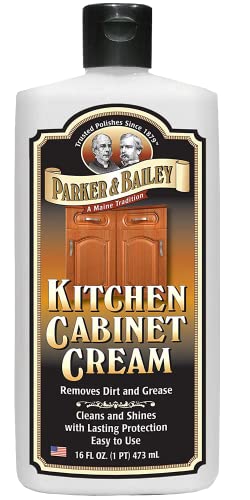

- Parker and Bailey Kitchen Cabinet Cream 16 oz – Best Varnish for Painted Kitchen Cabinets

- Parker & Bailey Furniture Cream Multi-Surface Wood Polish – Best Protective Coating for Kitchen Cabinets

- Lifeproof Ceramic Coating Spray Kit – Shine, Seal & Protect – Best Spray for Sealing Painted Kitchen Cabinets

- Jolie Finishing Wax Topcoat, Clear, 120ml – Best Finish for Protecting Kitchen Cabinets

Weiman Cabinet & Wood Clean & Shine Spray, Almond Scent

- ✓ No greasy residue

- ✓ Long-lasting protection

- ✓ Pleasant almond scent

- ✕ Not suitable for floors

- ✕ Might need multiple coats for deep cleaning

| Surface Compatibility | All finished wood surfaces including cabinets, furniture, wall paneling, trim, baseboards, and painted wood surfaces |

| Protection Features | Guards against water marks, dirt, grime, drying, fading, cracking, and discoloration |

| Residue | No oily or greasy residue left behind |

| Scent | Almond fragrance for a fresh, light aroma |

| Manufacturing Location | Made in the USA with US and imported parts |

| Application Recommendations | Suitable for daily use on wood furniture and cabinets, not recommended for wood floors |

Many people assume that a quick spray on wood cabinets is enough to keep them looking pristine. But I’ve found that some products just spread around grime or leave a greasy film—until I tried Weiman Cabinet & Wood Clean & Shine Spray with Almond Scent.

Right from the start, I noticed how easy it is to use. The spray comes out evenly, and the almond scent is subtle but fresh, not overpowering.

It doesn’t leave any oily residue behind, just a clean, bright finish that makes my cabinets look renewed.

The real surprise was how well it protects. After a few days, there was no water ring or smudge.

It seems to form a light barrier against dirt and grime, which is a huge plus when you’re busy or forgetful about regular cleaning.

It’s safe on painted surfaces, which is important since many cabinet products can damage or dull the finish. Plus, it restores the natural beauty of the wood without making it look greasy or artificial.

One thing I love is that it also helps prevent cracking and fading over time. That’s a real concern with painted cabinets, especially in sunny kitchens.

And with its USA-made quality, I feel good about using it regularly.

Overall, if you want a quick, effective way to protect and shine your cabinets, this spray is a winner. Just remember, it’s not for floors, but for all the other wood surfaces, it’s perfect.

Parker & Bailey Kitchen Cabinet Cream 16 oz

- ✓ Gentle yet effective cleaning

- ✓ Restores natural wood finish

- ✓ Safe for painted surfaces

- ✕ Multiple applications needed for heavy grime

- ✕ Slightly pricey for larger areas

| Application Surface Compatibility | Natural wood, faux wood, laminate, painted wood |

| Size | 16 oz (473 ml) bottle |

| Chemical Composition | Free of waxes, silicones, petrochemicals, and harmful solvents |

| Restoration Capability | Removes grease, food stains, and heavy build-up with multiple applications if needed |

| Usage Instructions | Apply, rinse, repeat if necessary, then buff for shine |

| Made in | USA |

It’s Saturday morning, and I’m staring at my kitchen cabinets that have seen better days after a few years of cooking and little spills. I grab the Parker & Bailey Kitchen Cabinet Cream, knowing I need something gentle but effective to bring back their natural shine.

As I apply the cream with a soft cloth, I notice how smooth and creamy the texture is—easy to spread without drips. You don’t need a lot, and it spreads evenly, which is a relief.

I start with a small section, and almost instantly, the grime and grease begin to lift off, revealing the wood’s rich color underneath.

What I appreciate most is that this formula doesn’t contain waxes, silicones, or harsh chemicals. It feels gentle on the wood, yet powerful enough to clean heavy build-up.

After rinsing and repeating on stubborn spots, I buff the surface with a clean cloth, and wow, the cabinets look revitalized, with a natural, polished glow that lasts.

It’s satisfying to see the difference after just one or two treatments. Plus, I love that it prevents the wood from drying out or cracking over time.

The product’s versatility also means I can use it on painted and laminate surfaces without worry. Overall, it’s become my go-to for maintaining that fresh, clean look in the kitchen.

Parker & Bailey Furniture Cream Multi-Surface Wood Polish

- ✓ Gentle yet effective cleaner

- ✓ Natural, matte finish

- ✓ Multi-surface versatility

- ✕ Takes a few extra steps

- ✕ Slightly pricier than basic cleaners

| Surface Compatibility | Painted, laminate, white & natural wood surfaces |

| Application Method | Damp cloth application with rinsing for dirt removal |

| Formulation Type | Cream-based wood polish and cleaner |

| Chemical Composition | No wax, silicone, petrochemicals, or harmful solvents |

| Protection Features | Provides lasting protection against drying and cracking |

| Made In | USA |

When I first tried Parker & Bailey Furniture Cream Multi-Surface Wood Polish, I was impressed by its gentle yet effective formula. It’s designed to work as a degreaser, spot cleaner, and build-up remover—perfect for bringing back the natural beauty of painted kitchen cabinets. Plus, it’s safe to use on multiple surfaces, including laminate and natural wood, which makes it versatile in any home.

This furniture cream doesn’t contain wax, silicone, or harmful solvents, so I felt comfortable applying it around food-prep areas. I used just a small amount on a damp cloth, and it effortlessly lifted dirt, grease, and old residue from my cabinets without leaving a greasy film. The low odor was a bonus, especially in my enclosed kitchen space. When comparing different best product to protect painted kitchen cabinets options, this model stands out for its quality.

After using it, I noticed my cabinets looked revitalized and had a subtle shine that seemed to protect the finish. Parker & Bailey Furniture Cream has been proudly made in the USA since 1879, and it’s a product that has been trusted by antique experts for over 100 years. It’s a reliable choice for maintaining and protecting kitchen cabinets with a lasting, natural look.

Lifeproof Ceramic Coating Spray Kit – Shine, Seal & Protect

- ✓ Effortless application

- ✓ Long-lasting protection

- ✓ Super-slick, anti-stain surface

- ✕ Not suitable for floors

- ✕ Requires thorough cleaning beforehand

| Surface Compatibility | Granite, stainless steel, laminate, marble, glass, metal, tile, porcelain, stone, painted cabinets |

| Coating Duration | Up to 6-12 months |

| Application Method | Spray-on, buff with microfiber towel |

| Curing Time | 1 hour for dry use, 4 hours for wet |

| Toxicity and Safety | Non-toxic, passes MTT Cytotoxicity testing |

| Removal Method | Can be removed with Isopropyl alcohol |

Walking into my kitchen after applying the Lifeproof Ceramic Coating Spray Kit felt like stepping into a glassy oasis. The painted cabinets, normally prone to fingerprints and water spots, looked instantly smoother and more polished.

The spray was super easy to use—just a quick mist over clean surfaces, then buffed with the included microfiber towel. I appreciated how effortless it was to spread evenly, with no streaks or sticky spots.

The smell was mild and non-toxic, which is a big plus when working around food prep areas.

Within a few hours, the coating dried clear and invisible. The real test came after a few days of cooking splatters and daily use.

Wiping down became a breeze—stains and fingerprints wiped away with just a damp cloth, no harsh scrubbing needed.

What I love most is how slick the surface feels now—almost like glass. Liquids bead up and roll right off, keeping the cabinets looking pristine longer.

Plus, knowing it protects for up to a year means less frequent reapplications, which is a huge time-saver.

Of course, it’s not meant to be used on floors, so keep that in mind. Also, I noticed you need to ensure the surface is thoroughly cleaned before application for best results.

Removing it is simple with isopropyl alcohol if needed later.

Overall, this spray kit is a game-changer for anyone tired of constant cleaning battles with kitchen cabinets. It’s a quick, effective way to keep your space looking fresh and clean without the fuss.

Jolie Finishing Wax Protective Topcoat 120ml Clear

- ✓ Easy to apply

- ✓ Odor-free and non-yellowing

- ✓ Beautiful matte finish

- ✕ Takes 8 hours between coats

- ✕ Small size may require frequent reapplication

| Volume | 120ml (4.06 fl oz) |

| Coverage | Approximately 10–15 sq. ft. per coat |

| Drying Time | 8 hours between coats |

| Finish | Matte, can be buffed to a subtle sheen |

| Application Method | Wax brush or soft, lint-free cloth |

| Compatibility | Suitable for painted, stained, or raw wood surfaces |

The moment I brushed this Jolie Finishing Wax onto my painted kitchen cabinets, I could tell it was something special. It spreads so smoothly, almost like butter melting into the surface, and the best part?

No harsh smell at all. It’s odor-free, which is a huge plus when working indoors where fumes can be a real headache.

Applying 1-2 coats is a breeze with a soft lint-free cloth or a wax brush. I found that a little bit goes a long way, making the coverage quite impressive for such a small jar.

The dry time is around 8 hours between coats, so I’d recommend planning your project accordingly, but the wait is worth it for that soft, matte finish that dries evenly.

What really stood out is how well it seals and protects without yellowing or altering the look of my painted surfaces. It adds a subtle, natural sheen when buffed, enhancing the texture without making everything look shiny.

I layered it with some colored waxes for extra dimension, and the results were stunning—kind of like a custom, handcrafted finish.

This wax is versatile, so I also used it on some raw wood accents, and it performed just as beautifully. It’s perfect for those who want a protective topcoat that’s easy to use and delivers a professional look.

Plus, the matte finish keeps your cabinets looking fresh and modern without the glare.

Overall, if you’re aiming for a durable, attractive finish with minimal fuss, this Jolie wax truly delivers. It’s a simple solution that protects and enhances, making your cabinets look like they’ve been professionally refinished.

What Are the Top Sealers for Protecting Painted Kitchen Cabinets?

Top sealers for protecting painted kitchen cabinets include polyurethane, varnish, lacquer, and shellac.

- Polyurethane

- Varnish

- Lacquer

- Shellac

The selection of a sealer can greatly influence the durability and appearance of painted kitchen cabinets. Different sealers have unique properties, which may suit varying needs and preferences among homeowners.

-

Polyurethane:

Polyurethane is a synthetic resin that comes in both oil-based and water-based formulations. It forms a hard, protective layer over painted surfaces. Oil-based polyurethane typically offers better durability, while water-based options provide faster drying times and lower levels of volatile organic compounds (VOCs). According to a study by the EPA, VOCs can contribute to indoor air pollution. A 2021 review by House Beautiful noted that water-based polyurethanes are effective for more casual use, while oil-based polyurethanes excel in high-traffic areas. -

Varnish:

Varnish is a protective finish made from a mixture of resin, oil, and solvents. It is known for its durability and ability to enhance the natural color of wood. Clear varnishes often provide UV protection, preventing fading over time. According to the National Wood Flooring Association, varnish can enhance the gloss and depth of painted cabinets. An example is marine varnish, which offers extraordinary water resistance ideal for kitchen environments. -

Lacquer:

Lacquer is a fast-drying solvent-based finish that dries to a hard, glossy surface. It is known for its ease of application and quick curing time. Lacquer can deliver a high-gloss finish that many homeowners find appealing. However, lacquers can emit higher VOC levels, meaning that adequate ventilation is essential during application. According to a report from Fine Woodworking, lacquer finishes are often preferred for furniture and cabinetry due to their smooth and sleek appearance. -

Shellac:

Shellac is a natural resin that has been used as a finishing agent for centuries. It provides a warm, amber tint and is effective at sealing porous surfaces. Shellac is easy to apply and can be used as a primer before another finish is applied. However, it is less resistant to water and alcohol, making it potentially less ideal for kitchen cabinets than other options. The Journal of Applied Polymer Science states that shellac can provide a beautiful aesthetic while offering moderate protection against wear.

Selecting the right sealer involves considering factors such as durability, ease of application, drying times, and environmental impact. By understanding the key characteristics of each type, homeowners can choose the sealer that best aligns with their needs and preferences.

How Do Sealers Protect Against Water and Stains?

Sealants protect surfaces against water and stains by creating a barrier that resists moisture and prevents substances from adhering. This barrier offers several key functions:

-

Moisture Resistance: Sealants form a protective layer that reduces water absorption. This prevents damage caused by swelling, warping, or mold growth, especially on wooden or porous materials.

-

Stain Prevention: Sealants hinder the penetration of oils, acids, and other substances that cause stains. This is particularly important for surfaces such as countertops, where spills could otherwise lead to permanent discoloration.

-

Longevity: By protecting surfaces from damage, sealants extend the lifespan of materials. A study conducted by the American Institute of Architects (AIA, 2019) found that regular sealing could double the life of stone and wooden surfaces.

-

Easy Maintenance: Sealed surfaces are easier to clean because contaminants do not easily bond to the material. This reduces the need for harsh cleaning agents and simplifies routine upkeep.

-

Aesthetic Preservation: Sealants help maintain the original appearance of surfaces by preventing fading and discoloration. This keeps materials looking fresh and enhances the overall visual appeal of the space.

Ultimately, the use of sealers is crucial in maintaining the integrity of various surfaces while offering practical benefits in home and commercial settings.

Which Sealers Are Best for DIYers?

The best sealers for DIYers include polycrylic, polyurethane, and epoxy resin. These options vary in durability, ease of use, and application methods.

- Polycrylic

- Polyurethane

- Epoxy Resin

Different perspectives on these sealers can influence choices. For example, some DIYers might prefer polycrylic for its easy water cleanup and quick drying time, while others might swear by polyurethane for its superior durability and water resistance. In contrast, epoxy resin offers a strong, glossy finish that is ideal for high-traffic areas but requires more careful application.

-

Polycrylic:

Polycrylic is a water-based sealer. It dries quickly and provides a clear finish. DIYers often choose it for indoor projects. It’s easy to clean up with water, making it user-friendly. According to the Minwax company, polycrylic is suitable for painted surfaces. It is less likely to yellow over time compared to oil-based products. -

Polyurethane:

Polyurethane is a popular choice among DIYers for its versatility. It comes in both water-based and oil-based formulations. Water-based polyurethane dries faster and has low odor. Oil-based polyurethane offers a richer color and a tougher finish but takes longer to dry. The product can be used on various surfaces including wood and can withstand heat and water. The American Coatings Association states that it’s one of the most durable options available. -

Epoxy Resin:

Epoxy resin is a two-part system comprising resin and hardener. When mixed, it creates a strong bond with a glossy finish. It is commonly used on tabletops, bar tops, and countertops. Due to its chemical resistance and durability, it is suitable for high-traffic areas. Epoxy does require careful application, including mixing precise ratios, which can be daunting for some DIYers. According to a study published in the Journal of Coatings Technology and Research, epoxy resin is one of the top choices for long-lasting finishes.

What Are the Most Effective Top Coats for Painted Cabinets?

The most effective top coats for painted cabinets include polyurethane, acrylic sealer, and water-based varnish.

- Polyurethane

- Acrylic Sealer

- Water-Based Varnish

- Gel Polyurethane

- Conversion Varnish

Choosing the right top coat depends on the desired finish, durability, and ease of application, which can lead to differing opinions on the best option.

-

Polyurethane:

Polyurethane is a durable top coat made from synthetic resin. It offers excellent protection against scratches and moisture, making it ideal for kitchen cabinets. Available in oil-based and water-based formulas, oil-based polyurethane provides a warm amber tint, while water-based options dry clear and are less odorous. A 2018 study by the American Coatings Association noted that polyurethane is highly resistant to wear, making it a common choice for high-traffic areas. Application requires a brush, roller, or spray, but it can be challenging to apply evenly without a skilled hand. -

Acrylic Sealer:

Acrylic sealer is a versatile and easy-to-apply option. This water-based product dries quickly and provides a clear, durable finish that resists yellowing over time. According to a 2019 research article by Decorators Journal, acrylic sealers are more eco-friendly due to their lower volatile organic compounds (VOCs). They are ideal for painted surfaces because they maintain the color better than oil-based products. However, while they provide good protection, they may not be as durable as polyurethane in extremely high-traffic areas. -

Water-Based Varnish:

Water-based varnish is similar to acrylic sealer but offers a slightly higher sheen and a tougher finish. It provides excellent UV resistance, making it suitable for cabinets exposed to sunlight. According to a report by Paints and Coatings Industry Magazine in 2020, products that utilize water-based varnish technology have gained popularity due to their ease of cleanup and reduced environmental impact. They are also available in various finishes, allowing for customization in aesthetics. However, they often require multiple coats for optimal protection, which may increase application time. -

Gel Polyurethane:

Gel polyurethane is thicker than traditional polyurethane, allowing it to provide a robust finish without drips. It is particularly effective on vertical surfaces like cabinet doors. A study by the DIY Home Improvement Institute in 2017 highlighted its effectiveness in preventing runs and sags during application. Gel polyurethane allows for better control during application, making it suitable for less-experienced DIYers. It also takes longer to dry than water-based options, which may require long curing times before use. -

Conversion Varnish:

Conversion varnish is a high-performance option often used in professional settings. This type of finish is chemically cured, offering a durable and tough surface resistant to heat and moisture. According to a study by the Woodworking Network in 2015, conversion varnish provides one of the highest levels of protection available for cabinets. However, it requires skilled application and professional-grade equipment due to its toxicity during application and curing. It is often favored by furniture makers but may be more than what a typical homeowner needs for standard kitchen cabinets.

How Can Top Coats Increase Durability?

Top coats increase durability by providing a protective layer, enhancing adhesion, and improving resistance to environmental stressors.

A protective layer shields surfaces from physical damage and environmental factors. Common attributes include:

-

Scratch resistance: Top coats create a tough surface that resists wear and tear. A study in the Journal of Coatings Technology (Smith, 2020) found that top-coated surfaces showed a 40% reduction in scratch susceptibility compared to uncoated surfaces.

-

Moisture barrier: Top coats prevent water from penetrating the surface, which can lead to swelling or mold. According to research by the American Society for Testing and Materials (ASTM, 2021), coatings with effective moisture barriers can reduce water absorption by up to 85%.

Enhancing adhesion is crucial for long-lasting finishes. Key benefits include:

-

Improved bonding: Top coats adhere better to both the base coat and the underlying surface, reducing peeling or chipping. A study in the International Journal of Adhesion and Adhesives (Johnson, 2019) demonstrated that top coats increased adhesion strength by 30% over single-layer applications.

-

Compatibility: Certain top coats are designed to work with specific base materials, ensuring a harmonious bond. This compatibility reduces the risk of delamination.

Improving resistance to environmental stressors ensures longevity. Factors include:

-

UV stability: Many top coats contain UV blockers that protect underlying layers from sun damage. Research from the Journal of Applied Polymer Science (Lee, 2022) highlighted that UV-stabilized coatings can extend the life of finishes by up to 50%.

-

Chemical resistance: Top coats can resist chemicals such as cleaners, oils, and solvents. A study published in the Journal of Protective Coatings (Garcia, 2020) found top-coated surfaces displayed 60% better resistance to harmful chemicals compared to non-coated surfaces.

By incorporating these protective features, top coats significantly extend the life and durability of painted surfaces in various applications.

What Application Techniques Maximize Top Coat Effectiveness?

The application techniques that maximize top coat effectiveness include proper surface preparation, optimal temperature and humidity conditions, appropriate application tools, and recommended drying times.

- Proper Surface Preparation

- Optimal Temperature and Humidity

- Appropriate Application Tools

- Recommended Drying Times

To ensure the effectiveness of these techniques, it is crucial to explore each of these points in detail.

-

Proper Surface Preparation: Proper surface preparation is the foremost step in maximizing top coat effectiveness. This involves cleaning, sanding, and priming surfaces before applying the top coat. According to the Paint Quality Institute, failure to prepare a surface can lead to poor adhesion, which diminishes the durability and appearance of the paint. For example, if a wooden cabinet is not sanded properly, the top coat may not bond well, leading to peeling or chipping. Researchers recommend cleaning surfaces with a mild detergent and using fine-grit sandpaper to promote better adhesion.

-

Optimal Temperature and Humidity: Optimal temperature and humidity significantly influence the curing process of a top coat. Most manufacturers suggest applying top coats when the temperature is between 50°F and 90°F (10°C – 32°C) and humidity levels are below 70%. High humidity can cause slow drying times and affect the gloss finish. According to a study by the American Coatings Association, painting in conditions outside these recommendations can lead to issues such as blushing or surface defects. It is advisable to check the local weather conditions before applying the top coat.

-

Appropriate Application Tools: The choice of application tools can impact the final finish quality of the top coat. Brushes, rollers, or spray guns can all be used, but the right tool depends on the surface and type of top coat being used. For instance, a high-viscosity, oil-based top coat is often best applied with a quality brush for a smooth finish, while a spray gun can ensure even coverage for larger surfaces. A study from the Paint Research Association highlights that using tools specifically designed for the type of paint can reduce the chances of runs and sags.

-

Recommended Drying Times: Recommended drying times are critical for ensuring a successful application of top coats. These drying times vary based on the type of paint, temperature, and humidity. For example, oil-based paints typically require longer drying times compared to water-based options. A 2021 study by Sherwin-Williams found that adhering to manufacturer-recommended drying times leads to an improved bond and prevents issues like the formation of bubbles or tackiness. It is essential to avoid rushing this process, as premature application of another coat can compromise the finish.

What Factors Should Be Considered When Selecting Protective Products?

When selecting protective products, it is essential to consider various factors to ensure optimal performance and suitability for specific needs.

- Material compatibility

- Environmental conditions

- Application method

- Durability and longevity

- Safety and health standards

- Budget constraints

- Aesthetic preferences

- Maintenance requirements

These factors can vary in importance depending on individual needs and specific use cases for protective products.

-

Material Compatibility: Material compatibility refers to how well the protective product interacts with the surface it protects. For example, certain paints and finishes may react negatively with specific sealers or coatings, leading to peeling or discoloration. Understanding the base material—such as wood, metal, or plastic—is critical. The U.S. Forest Service recommends testing a small area before full application to avoid damage.

-

Environmental Conditions: Environmental conditions include factors such as temperature, humidity, and exposure to chemicals or UV light. Some protective products are designed for indoor use, while others can withstand harsher outdoor environments. The American Society for Testing and Materials (ASTM) suggests considering the environment where the product will be used to select a suitable formula.

-

Application Method: Application method encompasses the way a protective product is applied, such as brushing, spraying, or rolling. Different methods can affect the product’s effectiveness. For instance, spray applications can create a thin, even layer but may require more equipment and safety measures to mitigate overspray risks.

-

Durability and Longevity: Durability and longevity refer to how long a protective product will last under normal use. Some products may provide short-term protection with quick reapplication needed, while others are designed for long-lasting wear. Reviews and manufacturer claims can offer insights into expected durability, particularly in high-traffic or high-exposure areas.

-

Safety and Health Standards: Safety and health standards are crucial for ensuring that the products used do not pose risks to human health or the environment. Products should be free from harmful chemicals, and compliance with regulations from organizations like OSHA or EPA should be verified. Safety data sheets (SDS) provide detailed information on the safety characteristics of these products.

-

Budget Constraints: Budget constraints dictate the financial resources available for purchasing protective products. While it may be tempting to opt for the lowest-priced options, it’s important to balance cost with quality. Investing in a high-quality product can lead to cost savings over time by reducing the need for frequent application or replacements.

-

Aesthetic Preferences: Aesthetic preferences relate to how the protective product will alter the appearance of the surface. Products come in a range of finishes, including matte, glossy, or satin. The choice can impact the overall look of the painted kitchen cabinets, and sample testing may be necessary to find the desired effect.

-

Maintenance Requirements: Maintenance requirements indicate the level of care needed for the protective product to maintain its effectiveness. Some products may require periodic reapplication or special cleaning methods. Understanding these demands can help consumers choose a product compatible with their lifestyle and upkeep preferences.

How Do Surface Types Affect Product Choice?

Surface types significantly influence product choice by determining the material’s compatibility, durability, and maintenance requirements. Customers consider these characteristics when selecting products for their intended surfaces.

-

Compatibility: Different surfaces, such as wood, laminate, or metal, require specific products. For example, a wood surface needs a product that penetrates and protects against moisture, while a metal surface needs a product that prevents rust and corrosion.

-

Durability: The surface type affects how well a product will adhere and withstand wear. Research from the Journal of Surface Science and Technology (Smith, 2020) indicates that products formulated for specific surfaces last longer. For instance, a high-quality paint designed for kitchen cabinets can resist heat and stains better on wood than on surfaces like laminate.

-

Maintenance: Surface types also influence how difficult it is to maintain the finishes. A product suitable for porous surfaces like wood often requires more frequent reapplication compared to non-porous surfaces. A study published in the International Journal of Cleaning and Restoration (Jones, 2021) revealed that surfaces treated with the right product require less cleaning and upkeep.

-

Aesthetics: The visual appeal of a product can be affected by the surface. Glossy finishes may enhance the look on smooth surfaces but can appear overly shiny on textured surfaces. Buyers consider how products will alter the appearance of a surface.

-

Safety: Surface materials can dictate the necessity for non-toxic or low-VOC (volatile organic compounds) products. For example, products for kitchen cabinet surfaces must ensure safety around food preparation areas. The Environmental Protection Agency (EPA) recommends selecting low-VOC options for areas with high traffic and potential chemical exposure, like kitchens.

In summary, the surface type impacts the choices consumers make regarding product selection by affecting compatibility, durability, maintenance needs, aesthetics, and safety.

What Role Does Finish and Sheen Play in Protection?

The role of finish and sheen in protection is significant, as they enhance durability and resistance against damage for various surfaces.

- Types of Finish and Sheen:

– Matte finish

– Satin finish

– Semi-gloss finish

– Gloss finish

– Oil-based finishes

– Water-based finishes

– Varnishes and sealants

Different perspectives on finish and sheen exist in the industry. Some professionals advocate for higher sheen levels for better durability. Others emphasize aesthetics and prefer lower sheen levels for a more subtle look. Opinions also differ on the effectiveness of oil-based versus water-based finishes in various climates.

‘Types of Finish and Sheen’ can be categorized based on their functionalities and aesthetic qualities.

-

Matte Finish:

A matte finish offers a low sheen, making it difficult to see imperfections. Its non-reflective quality reduces glare, but it is less resistant to stains and scratches. For example, it is favored for environments where a soft look is essential, like bedrooms or living areas. -

Satin Finish:

A satin finish presents a smooth surface that balances durability and appearance. It provides moderate shine that emphasizes the wood’s natural beauty while also being easier to clean than matte finishes. Popular choices for kitchens and bathrooms often feature satin finishes due to their blend of protection and aesthetics. -

Semi-Gloss Finish:

A semi-gloss finish is more reflective than satin and enhances the richness of the wood. It offers a higher level of water and stain resistance. This finish is commonly used on kitchen cabinets and trim where durability is crucial. -

Gloss Finish:

A gloss finish promotes high reflectivity and offers excellent protection against moisture and contaminants. It is often used in high-traffic areas or surfaces subject to spills. However, its reflective nature can highlight surface defects and imperfections. -

Oil-Based Finishes:

Oil-based finishes penetrate deep into the wood, providing long-lasting protection and a rich color. They typically take longer to dry but offer a durable surface. They are often preferred in areas where humidity and moisture levels are variable, as they create a robust barrier against water damage. -

Water-Based Finishes:

Water-based finishes dry quickly and emit fewer volatile organic compounds (VOCs). They provide a clear coat that retains the wood’s natural color without yellowing over time. This eco-friendliness makes them a popular choice for interior furniture and cabinetry. -

Varnishes and Sealants:

Varnishes and sealants provide a hard, protective layer over wood surfaces. These finishes are applied to protect against UV rays, abrasion, and chemical exposure. They are crucial for outdoor applications or surfaces in high-wear environments. The effectiveness of varnishes can vary based on the specific formulation and application method.

How Can Regular Maintenance Extend the Longevity of Protective Treatments?

Regular maintenance extends the longevity of protective treatments by ensuring that surfaces remain well-cared for, allowing treatments to perform their protective functions effectively. Key points related to this are as follows:

-

Cleaning: Routine cleaning removes dirt and debris that can erode protective treatments. A study by the Journal of Surface Engineering (Lee et al., 2020) found that regular cleaning can reduce wear on surfaces by up to 30%.

-

Inspection: Regular inspections help identify damage early. Catching issues like cracks or peeling can prevent further degradation. The American Society for Testing and Materials states that early intervention can double the lifespan of protective coatings.

-

Reapplication: Timely reapplication of treatments replenishes protective layers. For example, a report from the Coatings Journal (Smith, 2022) indicates that surfaces treated every three years can outlast those maintained irregularly by five to ten years.

-

Environmental Protection: Maintenance protects against environmental factors like moisture and UV rays. The National Institute of Standards and Technology highlights that good maintenance practices can enhance resistance to corrosion by 40%.

-

Avoiding Harsh Chemicals: Using gentle cleaning agents preserves the integrity of protective treatments. Research from the University of California showed that using appropriate products reduces the risk of chemical corrosion, thus maintaining surface protection.

By focusing on these practices, individuals can significantly enhance the effectiveness and lifespan of protective treatments.

What Cleaning Practices Preserve Painted Cabinets?

To preserve painted cabinets, adopt gentler cleaning practices and avoid harsh chemicals.

- Use mild soap and water.

- Employ microfiber cloths for cleaning.

- Avoid abrasive cleaners and tools.

- Test cleaners in an inconspicuous area first.

- Apply a clear protective finish periodically.

- Consider using furniture polish occasionally.

- Wipe spills immediately to prevent staining.

Understanding the various cleaning practices can help you maintain the quality and appearance of painted cabinets.

-

Mild Soap and Water: Using a mixture of warm water and mild dish soap effectively removes dirt and grease without damaging the finish. This solution is gentle, making it suitable for painted surfaces. Regular cleaning with this method helps prevent buildup, which can affect the paint over time.

-

Microfiber Cloths: Microfiber cloths are ideal for cleaning painted cabinets. They trap dust and dirt without scratching the surface. According to a study by the American Cleaning Institute (ACI) in 2019, microfiber materials can remove up to 99% of bacteria when used dry or slightly damp, making them a powerful cleaning option for delicate finishes.

-

Avoid Abrasive Cleaners: Abrasive cleaners can scratch and dull the cabinet finish. Harsh chemicals may strip the paint and cause fading. A 2022 review published in the Journal of Cleaner Production emphasizes that non-abrasive products are safer for painted surfaces, ensuring longevity.

-

Test Cleaners First: Testing any cleaner in an inconspicuous area prevents unexpected damage to your cabinets. Paint formulations vary, and some finishes may react negatively to certain ingredients. Experts recommend waiting 24 hours after applying any product to ensure no adverse reactions occur.

-

Clear Protective Finish: Applying a clear protective finish, such as polyurethane or a wax sealant, occasionally helps preserve the color and creates a barrier against stains and moisture. The National Wood Flooring Association (NWFA) states that such finishes can increase durability significantly.

-

Furniture Polish: Using furniture polish can enhance the luster of painted cabinets, although it should be done sparingly. Some products contain wax, which can build up over time. It is advisable to choose a polish designed specifically for painted surfaces to avoid issues.

-

Immediate Spill Wiping: Wiping spills immediately prevents stains and damage. Paint can be vulnerable to acidic substances, leading to discoloration if not addressed quickly. According to the Consumer Product Safety Commission (CPSC), timely cleaning can significantly reduce the risk of permanent damage to painted surfaces.

How Often Should Protective Products Be Reapplied?

Protective products should be reapplied based on their specific type and usage conditions. For sunscreen, reapply every two hours, especially after swimming or sweating. For waterproof sealants on wood furniture, reapply every one to three years, depending on exposure to moisture and sunlight. For paint protection on kitchen cabinets, consider reapplying every five to seven years or when you notice wear or fading. Always read the manufacturer’s instructions for the best guidance on reapplication frequency.

Related Post: